04

2022

-

11

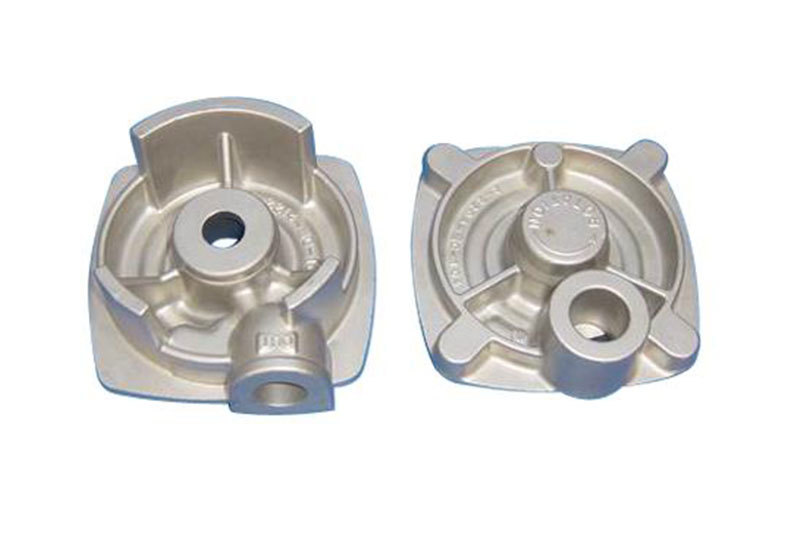

What are the properties of china Forktip Casting products

author:

china Forktip Casting products Theoretical liquid metal forming of castings is often called casting, and casting forming technology has a long history. As early as more than 5,000 years ago, our ancestors were able to cast copper and bronze products. china Forktip Casting products is the most widely used metal liquid forming process. It is a method of pouring liquid metal into the mold cavity, and after it cools and solidifies, a blank or part of a certain shape is obtained.

china Forktip Casting products occupies a large proportion of liquid molding parts in machinery and equipment. Liquid molding parts account for 70%~90% of the total weight in machine tools, internal combustion engines, mining machinery, and heavy machinery; 50%~ in automobiles and tractors 70%; 40% to 70% in agricultural machinery. The liquid forming process can be used so widely because it has the following advantages:

(1) china Forktip Casting products can manufacture blanks with complex inner cavity and shape. Such as various boxes, machine bed, cylinder block, cylinder head and so on.

(2) china Forktip Casting products have great process flexibility and wide adaptability. The size of the liquid molding is almost unlimited, and its weight can range from a few grams to several hundreds of tons, and its wall thickness can range from 0.5mm to 1m. Any metal material that can be melted into a liquid in the industry can be used for liquid molding. For very ductile cast iron, liquid forming is the only way to produce a blank or part.

(3) The cost of liquid molding parts is low. Liquid molding can directly use waste parts and chips, and the equipment cost is low. At the same time, the machining allowance of liquid forming parts is small, which saves metal.

Related News

Contact: Manager Huang

Tel:+86-18363688899

Email:info@junlongcast.com

Fax:+86-536-7669966

Address: South of Dongshou Road, Bama Road, Fangzi Old District, Weifang City, Shandong Province, China

Copyright © 2022 Weifang Junlong Machinery Co., Ltd.