ABOUT JIUNLONG

FACTORY DISPLAY

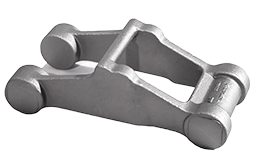

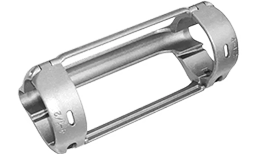

Junlong Machinery covers an area of 60,000 square meters. It has very complete investment casting production equipment, machining equipment and advanced physical and chemical analysis and testing equipment, with an annual production capacity of more than 10,000 tons.

JUNLONG QUALITY

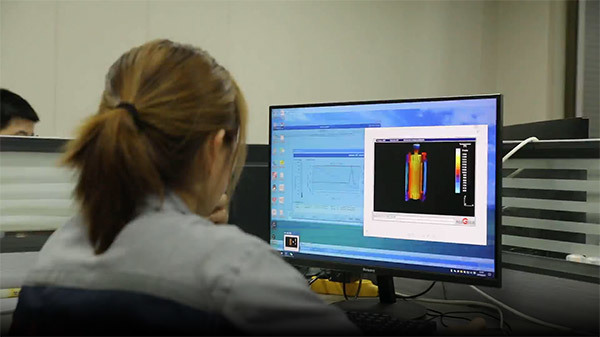

QUALITY CONTROL

We listen carefully to the requirements of our customers and provide full assistance. The aim is to make products that are 100% precise and accurate.

When the product has unforeseen problems or the customer has special requirements for precision castings

We will deal with it immediately and fully support it so that customers can get the goods they need faster.

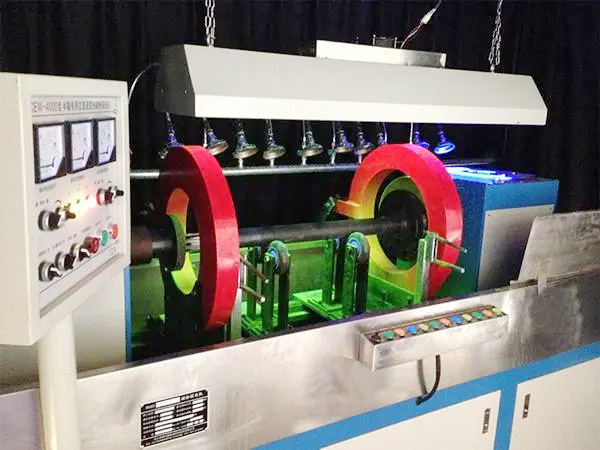

Magnetic particle flaw detector

CMM

OBLF spectrometer

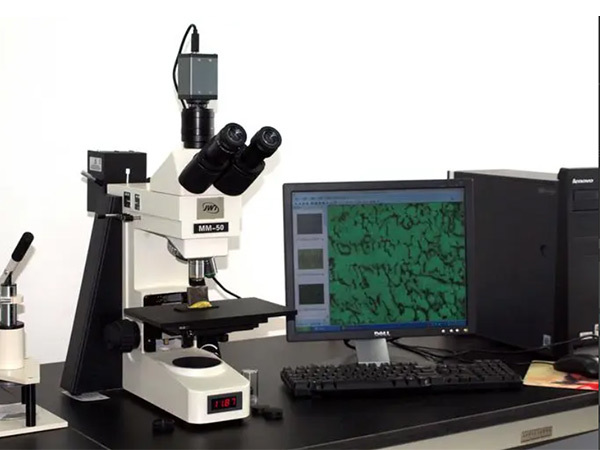

metallographic microscope

Quality Assurance

We will start from four aspects

Guaranteed to provide precise and accurate products

SGS Material detection

TS16949

ISO9001

Product patent

NEWSEVENTS

JUNLONG NEWS

07-24

The Importance of Design in Precision Casting

**Introduction** Precision casting, also known as investment casting, is a manufacturing process used to create complex and intricate parts for various industries, including engineering and construction machinery. One of the critical factors that determine the success of precision casting is the design of the components. In this article, we will explore the importance of design in precision castin

07-19

All You Need to Know About Alloy Steel Precision Casting in Manufacturing Machinery

Alloy steel precision casting is a manufacturing process that involves creating complex and intricate parts with high accuracy and precision. This process is widely used in the production of various components for engineering and construction machinery. The use of alloy steel in precision casting offers several advantages, including improved strength, durability, and resistance to wear and tear. O

07-14

Carbon Steel Precision Casting: A Key Component in Engineering Machinery

**Introduction** Carbon steel precision casting is a vital component in the manufacturing and processing machinery industry. It plays a crucial role in the production of engineering machinery and its various applications. In this article, we will delve into the importance of carbon steel precision casting, its benefits, applications, and why it is considered a key component in engineering machiner

07-09

Exploring the Intriguing Process of Lost Wax Casting in Manufacturing Machinery Parts

Lost wax casting, also known as investment casting, is a manufacturing process that has been used for centuries to create intricate and complex metal parts. In the realm of engineering and construction machinery, this technique plays a vital role in producing high-quality components that meet stringent performance standards. The process of lost wax casting begins with the creation of a wax model o

Contact: Manager Huang

Tel:+86-18363688899

Email:info@junlongcast.com

Fax:+86-536-7669966

Address: South of Dongshou Road, Bama Road, Fangzi Old District, Weifang City, Shandong Province, China

Copyright © 2022 Weifang Junlong Machinery Co., Ltd.