FACTORY DISPLAY

工厂实景

竣龙机械占地面积6万平方米,拥有十分完善的熔模精密铸造生产设备、机加工设备和先进的理化分析、检测设备,年生产能力10000吨以上

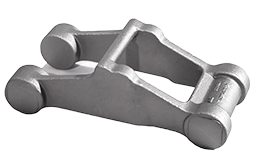

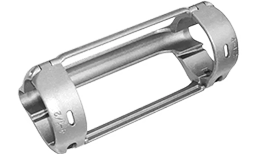

High precision custom carbon steel lost wax investment casting products

Our company adopts silico-sol sodium silicate composite process to produce high-quality precision casting parts. While ensuring casting quality, it reduces the cost by 30% to the final customer and improves the market competitiveness of the customer.

Our company adopts silico-sol sodium silicate composite process to produce high-quality precision casting parts. While ensuring casting quality, it reduces the cost by 30% to the final customer and improves the market competitiveness of the customer.OEM customized investment precision casting with ISO9001

Our company adopts silico-sol sodium silicate composite process to produce high-quality precision casting parts. While ensuring casting quality, it reduces the cost by 30% to the final customer and improves the market competitiveness of the customer. Including forklift parts in the steering system parts, lifting system parts, control system parts, etc., most of them are carbon steel and alloy steel precision casting parts, we can customize according to different materials

China High Quality Custom Stainless Steel/Carbon Steel Door Lock Precision Casting CNC Machining Service

Custom Steel Lost Wax Casting Lost Wax Casted Parts Supplier Machining Machinery Parts Precision Carbon Steel Casting

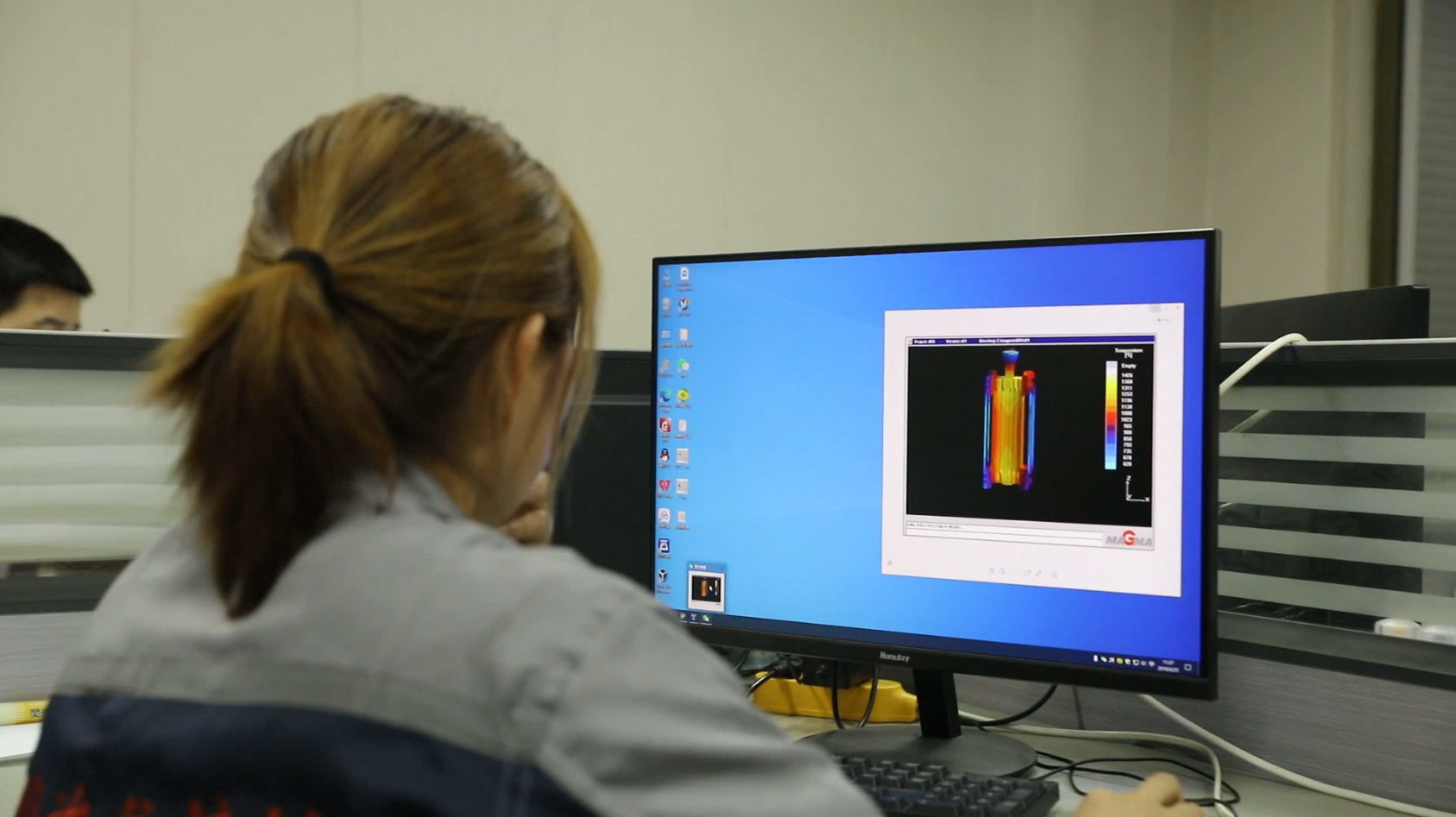

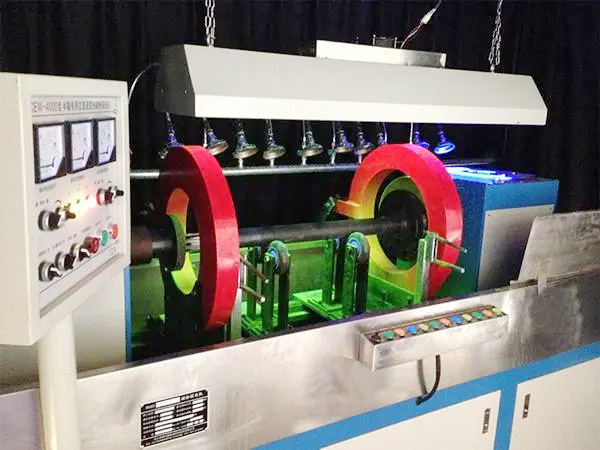

QUALITY CONTROL

质量控制

我们细心聆听客户的要求,全力协助。目的是制作百分百精密及准确的产品。当产品出现不可预见的问题或客户有精密铸件特别要求

我们会立即处理,全力支援,使客户更快地得到他们所需货品。

Magnetic particle flaw detector

CMM

OBLF spectrometer

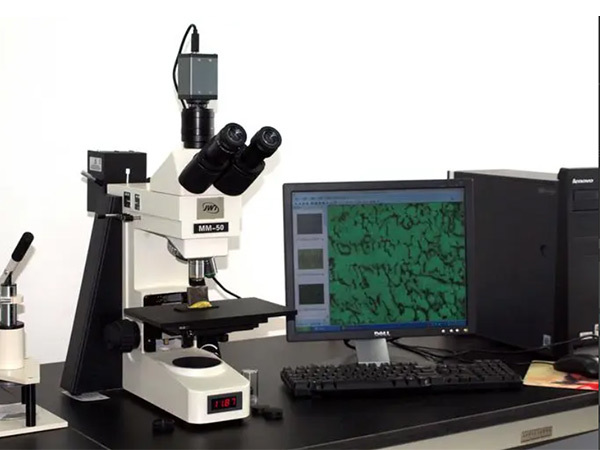

metallographic microscope

SGS材质检测

TS16949证书

ISO9001认证

产品专利

新闻动态

NEWS EVENTS

06-23

How to Effectively Store and Organize Your Construction Machinery Parts

How to Effectively Store and Organize Your Construction Machinery Parts In the fast-paced world of construction, the efficiency of your operations hinges significantly on how well you manage your machinery parts. An organized workspace not only saves time but also enhances productivity and equipment longevity. This guide will delve into best practices for storing and organizing your construction m

06-22

The Impact of Quality Construction Machinery Parts on Productivity: A Comprehensive Analysis

The Impact of Quality Construction Machinery Parts on Productivity Table of Contents 1. Introduction 2. The Importance of Quality Parts in Construction Machinery 3. Key Factors Affecting Productivity in Construction 4. The Relationship Between Parts Quality and Productivity 4.1 Downtime and Repair Costs 4.2 Safety and Worker Efficiency

06-21

Understanding the Different Types of Construction Machinery Parts: A Comprehensive Guide

Understanding the Different Types of Construction Machinery Parts Construction machinery plays a pivotal role in the efficiency and success of engineering and construction projects. The performance of these machines heavily relies on their parts, which can be categorized into various types. In this comprehensive guide, we will explore the different types of construction machinery parts, their func

06-20

Essential Tips for Finding Affordable Construction Machinery Parts

Essential Tips for Finding Affordable Construction Machinery Parts Understanding the Importance of Affordable Construction Machinery Parts When managing a construction business, the efficiency and longevity of your machinery are paramount. However, the cost of machinery parts can be a significant burden. Finding affordable construction machinery parts is not just about saving money; it's about ens

Contact: Manager Huang

Tel:+86-18363688899

Email:info@junlongcast.com

Fax:+86-536-7669966

Address: South of Dongshou Road, Bama Road, Fangzi Old District, Weifang City, Shandong Province, China

Copyright © 2022 Weifang Junlong Machinery Co., Ltd.